The Dangers of Static Electricity in Hazardous Areas: Awareness Training

Introduction

The purpose of this awareness training module is to consider the risk of fire or explosion posed by uncontrolled static electricity in a potentially explosive atmosphere or hazardous area, as will be found at manufacturing, processing and storage facilities covered by the UKEX, ATEX and IECEx directives.

We will look at the dangers related to static electricity and the methods that may be employed to mitigate the risks in relation to liquids, gases, powders, conductive plant and equipment, non-conductive plant and materials, as well as people.

This training does not include the control of “nuisance” static electricity in manufacturing processes that may hinder production but does not act as a source of ignition.

The Fire Triangle

For most fires to occur, there needs to be three things present: fuel, oxygen and an ignition source. These are often represented by ‘The Fire Triangle’.

In a potentially explosive atmosphere or hazardous area, the fuel that will sustain a fire is generally the product being produced or a necessary part of the manufacturing process. This could be a solvent, gas, flammable powder (including certain foodstuffs) or petroleum products. Hence, we can see that it would not be possible to remove the fuel to avoid a fire, in such environments.

Oxygen is, of course, all around us in the air and is therefore difficult to eliminate. It is possible to remove the oxygen in some circumstances, using nitrogen to replace it. This could be done in a container or room storing flammable materials. However, it has been found that the risk of suffocation can be a greater danger than that of fire. Hence oxygen removal is generally not considered to be a first option when looking to prevent fires.

The final component of the fire triangle is the ignition source. There are many examples of these in an industrial environment: hot surfaces that could cause certain gases to spontaneously combust, sparks from welding during maintenance that could ignite most vapours or unprotected electronic devices.

A less obvious, but equally dangerous source of ignition is a spark that may be released when static electricity is allowed to build up.

What is Static Electricity?

All physical objects are made up of atoms. Inside an atom are protons, electrons and neutrons. The protons are positively charged, the electrons are negatively charged, and the neutrons are, as you may expect, neutral.

Most of the time positive and negative charges are balanced in an object, which makes that object electrically neutral.

Static electricity, also often referred to as electrostatic, is the result of an imbalance between negative and positive charges in an object. These charges can build up on the surface (for example, as the result of two things rubbing together) until they find a way to be released or discharged. One way for them to discharge is by jumping, in the form of an electrical spark, to a nearby object with less or no electrical imbalance (known as a lower electrical potential).

Conductive materials allow electricity to pass through them whereas non-conductive materials prevent the passage of electricity: think of a conductive copper wire carrying electricity that is sheathed with a non-conductive plastic sleeve to prevent an electric shock if it is touched. It is very important to note that static electricity cannot accumulate on a metal or conductive object that is connected to earth (earthed) as the earth is taken to remain effectively at zero electrical potential. Note that ground, grounded or grounding are alternate terms to earth, earthed or earthing and mean the same things.

Static electricity occurs commonly in industry and everyday life. Many of the effects are harmless and either pass completely unnoticed or are simply a nuisance. Examples include the small shock you may feel when you reach out to open a car door, rubbing a balloon and making it stick to a wall or the crackling sensation when certain clothing is removed. Lightning is the extreme result of the build-up of electrostatic in clouds, being discharged to earth.

The UK HSE website highlights the document R044-001:1999 … Avoidance of Hazards due to Static Electricity as an accessible source of general advice and the later 60079-32 is available to purchase.

Static Electricity in Non-Conductive Solid Materials

Non-conductive solid materials are being used increasingly in equipment and structures in many forms including pipes, containers, coatings and liners and their use in hazardous areas can give rise to electrostatic hazards. These include the possibility of a conductive section of plant becoming isolated from earth by its non-conductive seals or flanges, allowing it to become charged and give rise to sparks, or charges on the surface of the non-conductive material could lead to brush discharges: another type of spark that may ignite a flammable atmosphere.

The use of non-conductive materials needs to be restricted in some hazardous areas. The restrictions depend on the zone classification of the hazardous area. The restriction on the size of chargeable surfaces depends on how easily the gases and vapours, likely to be present, may be ignited, as expressed by the representative groups IIA, IIB and IIC.

It is good practice to minimise the use of non-conductive materials in hazardous areas and today, many formerly non-conductive materials are available in versions which allow electrostatic to dissipate to earth and these are known as static-dissipative (or sometimes antistatic) materials. Choosing static-dissipative materials over their non-conductive equivalents will greatly improve the ability to control static.

Where conductive parts are separated by non-conductive materials, it is vital to ensure that metal bonding connections or earthing straps are made across the joints. These must always be refitted and checked if the equipment has been dismantled (perhaps for cleaning) and then reassembled.

Static Electricity in Liquids

The following requirements apply to common flammable liquids, such as organic solvents,

hydrocarbons, fuels and alcohols. Liquids can become electrostatically charged when there is relative movement between the liquid and adjacent solids, such as the pipe it is flowing in, or if there is a second component that does not mix, such as oil in water. Spraying or splashing of liquids can also create a highly charged mist or spray.

If the liquid has low conductivity (which can also be described as high resistivity), it is more likely to hold onto electrostatic charge. The conductivity of a liquid can be increased by using a few parts per million of a suitable antistatic additive, if the process allows. This will enable static electricity to pass from the liquid to earth, via the earthed pipe or container.

It should be noted that it is not the liquid itself that is flammable, but the vapour it gives off when it is above the temperature that allows this to occur, known as the flash point of the liquid. A low flash point liquid, such as petrol will give off vapour at normal plant operating temperatures and is therefore more susceptible to ignition from a static spark than a higher flash point liquid such as diesel. It should be noted that in an area where multiple products are being processed, or where a container is being used for a different product to previously (switch loading) a flammable atmosphere may be present even if the particular product being handled at the time has a very high flash point.

Earthing and Bonding Part 1

Before we consider static electricity in other materials, we will have a look at earthing and bonding as a primary means of controlling static electricity. As we saw earlier, when a conductive object is connected to earth, it cannot accumulate electrostatic charge. The officially recognised maximum resistance figure for the connection to earth is 1×10^6 or 1 million ohms. This figure may seem surprisingly high when compared to the sort of figure we look for when earthing for mains electrical systems, which is typically just 10 ohms and below. However, the 10^6 ohm value was derived as an upper limit for allowing static electricity to safely pass to earth, based on the known charging currents associated with the static-creating processes such as product transfer and mixing in modern production processes.

Details of these calculations may be found in R044-001 section 10.2.2, which also states that: Conductors in good contact with earth have a resistance to it of less than 10^6 ohms and, for convenience, a much lower resistance (in the range 10 ohms to 100 ohms) is often specified for monitoring. A clear distinction should be made between a value chosen for convenience, and the value of 10^6 ohms, which is the upper limit for the resistance to earth of a conductor in all situations. If a higher ohm value has been chosen for monitoring (for example, to aid with other features such as object recognition), it should be noted that such a system will have the same effectiveness at removing static electricity provided the figure is set below 1×10^6 ohms. What is most important, however, is that all connections are reliable, permanent and not subject to deterioration.

Fixed plant structures such as tanks, reactor vessels and pipes are generally found to be in good connection to earth and if this is the case, there is little risk of their connections deteriorating to above 10^6 ohms. If plant items are not in connection to the main earthed structure, for example those on flexible mountings or load cells, specific earth connections may be required.

There are items of equipment, such as drums, funnels and trolleys, which cannot be permanently connected to earth through the main plant structure. In many cases, their resistance to earth could be well below 10^6 ohms, but this cannot be relied upon. To prevent electrostatic charge build up, the minimum requirement is that each item should be earthed whenever a flammable mixture could be present and, at the same time, there is a possibility of electrostatic charging, such as during the filling or emptying of a container.

Temporary earthing connections should be sturdy, with cables made from a material such as steel, not liable to fracturing when moved around (as could be the case with weaker copper wires) and if a clamp is fitted, these should have teeth to ensure that they bite through contamination or a paint coating, to the metal item itself. These cables and clamps will be connected back to the main plant structure or earthing provision, which should have its resistance to earth tested periodically along with the cables and clamps themselves.

Static Electricity in Gases

The movement of pure gases or of a mixture of gases generates little, if any, static electricity but if the gases contain solid or liquid particles these can become charged. It is common to find such particles in industrial processes as a result of contamination or droplets in steam. It is not possible to prevent the electrostatic charging of particles, but ignition can be avoided by taking precautions to prevent incendive discharges, for example by:

– ensuring that all metal and other conducting objects are earthed.

– avoiding the use of highly resistive materials.

– reducing charge densities by restricting flow velocities or by suitable nozzle design.

– removing the particles.

Static Electricity in Powders

In this section, the term powder means particles with sizes ranging from those of fine dust up to granules or chips. The ease with which a given powder can be ignited by discharges or sparks due to static electricity is characterised by the minimum ignition energy (MIE) of the product and this generally depends on the fineness of the powder: the lowest energy required relating to very fine powder.

We will assume here that the powder is handled without any flammable gases and vapours being present in the process and that they could not be introduced from neighbouring processes. If vapour or gas is to be present, such as during the drying of a solvent enriched pharmaceutical powder, special precautions must be taken.

It is often incorrectly assumed that hazardous area equipment marked as being suitable for a Gas or vapour environment (denoted by the capital letter G) and a dust environment (denoted by the capital letter D) can be used where both gas and dust are present at the same time, but this is not actually the case: it is gas OR dust. If both are present, again special consideration must be made when selecting equipment.

Many powders will easily gain static electricity when they are being moved along pipes or flow into bulk containers. Unlike with liquids, anti-static additives are generally not available for use with powders and in some cases, it is not possible to prevent charge build up. In applications such as transferring grain or flour into a large storage silo, it is common to accept that an ignition caused by electrostatic discharge can occasionally occur and pressure relief panels are fitted to the silo so that as an explosion propagates, the panels are blown open and the pressure relieved, without causing uncontrolled damage to the silo.

Wherever possible, earthing and bonding of the plant, such as pipes and storage containers along with reduced flow speed of the powder, will help the static dissipate from the powder by allowing it to flow to earth although the charge relaxation time will increase, the more resistive the powder is.

Powders are often stored in FIBCs or flexible intermediate bulk containers made from insulating materials such as polypropylene and these would prevent static charge from dissipating safely. Hence the basic FIBCs are not suitable for use in hazardous areas. There are, however, more specialised types of FIBC that may be used safely:

Type C FIBCs contain interconnected conductive threads or filaments forming a grid within the fabric that connects to an earthing point. Conductivity through the bag structure to the earthing point should be less than 1×10^8 ohms. Although this maximum figure is higher than the 10^6 ohms stated elsewhere, it has been calculated to safely prevent charge build up on the Type C FIBC during filling and emptying operations.

Type D FIBCs are designed to remove charge by controlled low energy discharges, known as corona discharges, from the surface of the bag. When using Type D bags, it is essential that all nearby conductive objects, such as drums on a pallet, are earthed to prevent the corona discharges from the FIBC causing charging by induction. Type D FIBCs should not be used where IIC gases may be present.

Static Electricity on Persons

In former times, before synthetic materials existed, a person would wear leather shoes and natural fibre clothing and move about on the earth itself or floors made of stone or covered with rush matting. All these materials are static dissipative, meaning that static electricity would not build up on a person. One natural insulating material from the time was the resin we call amber and in ancient Greek, was known as elektron. The build-up of static on it, when being polished to make jewellery gave rise to the word electricity!

Today, synthetic soled shoes and synthetic fibre carpets isolate people from earth and as they move around, static electricity builds up on the body, especially if synthetic fibre clothing is worn. When the electrostatically charged person reaches out to say, a metal filing cabinet, a spark will jump from the body to the cabinet, which is at a lower electrical potential than the person, even if it is not earthed. Note that the energy is jumping from the person, not as is often incorrectly supposed, from the cabinet. If the spark is large enough to be felt or even hurt, it will contain more than enough energy to ignite most solvent or flammable gas atmospheres. Even a tiny spark that may not be felt can ignite the more sensitive or low minimum ignition energy vapours.

Hence it is important to prevent static electricity from building up on a person working in a hazardous atmosphere. This is best achieved by having a conducting or dissipative floor and ensuring that persons wear dissipative footwear.

In many factory environments the conventional flooring materials, for example, bare concrete or steel grids, are adequately conducting but should always be tested. To remain effective, the floor should not be covered by rubber mats, plastic sheets or be painted (unless with static-dissipative paint) and care should be taken to prevent the build-up of contaminants such as resin or other non-conductive substances.

Dissipative footwear has both an upper and a lower resistance requirement. The upper level, specified as 1×10^8 ohms, is low enough to prevent the build-up of electrostatic charge in most situations and the lower level offers some protection in the event of accidental contact with mains electricity. In order to check that a person such as a visitor is wearing the correct type of footwear, a commercially available footwear tester may be used. This will also serve to test the continued effectiveness of older footwear.

As mentioned, clothing can hold static electricity, but is not considered to be a major risk if the person is wearing suitable footwear. However, the excess of static electricity that can be generated when removing clothing means that this should not be done in a potentially explosive atmosphere. Disposable lab coats and over suits made of highly resistive non-woven materials are not recommended.

Earthing and Bonding Part 2

As we saw earlier, earthing and bonding of moveable items, which cannot be permanently connected to earth, is of particular importance. R044-001 section 10.4 states that:

Important features in the design of earthing devices are:

- a) They should be recognised as such and be accepted as essential to the safe operation of the plant.

- b) They should either be clearly visible or be essential to the correct functioning of the plant, so that

any shortcomings are quickly detected.

- c) They should be robust and so installed that they are not affected by high resistivity contamination,

for example, by corrosion products or paint.

- d) They should be easy to install and to replace.

- e) Cables for earthing moveable items should be equipped with a strong clip (or clamp) capable of penetrating through paint or rust layers. The clip (or clamp) should be attached before the operation commences and should remain in place until the operation has been finished and all hazardous electrostatic charges have been eliminated.

An aspect of electrostatic charge accumulation that we have not yet considered is the capacitance of a conductive object. The larger the capacitance of an object, the more charge it is able to store. One of the largest moveable items to be seen in industrial hazardous area operations is the road tanker, delivering or taking away product. As this will have a very large capacitance and is likely to take some time to be filled or emptied, the potential to build up charge and then release it in the form of a high energy spark is great.

The tyres of vehicles, including road tankers, have static dissipative properties to prevent the movement of the wheels from depositing charge on the vehicle body whilst being driven. However, the tyres are not considered to have a low enough resistance to earth to deal with the amount of charging that can occur during prolonged product transfer and hence a robust earthing connection is required. This should be attached to the tanker before any other operation, such as opening manways, connecting hoses or starting the transfer pump takes place and should remain in place until the operations are complete and the tanker is ready to leave.

Owing to the higher risk associated with road tankers, R044-001 section 5.4.4.3 states: “It is recommended that interlocks should be provided to prevent loading when the earthing cable is not connected” (to the road tanker). Interlocks tend to take the form of an earth monitoring system, that requires the earthing clamp to be connected before starting the transfer pump or opening an automated valve can occur. The earthing system will show a green light when a secure earth connection has been made and release the interlock to allow the operation to proceed. If the earth connection is interrupted, the interlock will cause the pump to shut down, stopping the process.

As the loading or unloading of a road tanker is often carried out under the supervision of the tanker driver, rather than the site’s own employees, it has become popular for an earth monitoring system to also include a tanker recognition feature to ensure that the clamp has been correctly fitted to the actual tanker and not simply to other surrounding metalwork in order to gain a permissive signal.

Earth monitoring systems are also available to work with rail tankers and whilst it is often considered that the rail tanker will be earthed via its wheels and the rails, some anomalies of the rail system may mean additional earthing is required, as described in R044-001 section 5.4.4.4. Special monitoring systems designed to detect an earth connection of less than 1×10^8 ohms are also available to work with the Type C FIBCs described earlier.

Conclusion

We trust that this awareness training has given an overview of the dangers of static electricity in hazardous areas and provided an insight into how static electricity may be controlled and the risks associated with it, reduced. When carrying out work to implement the control of static electricity in a hazardous area, it is recommended that the relevant sections of available guidance, such as document R044-001 or the standard 60079-32-1 be consulted.

It is very seldom that an electrostatic hazard can be treated in isolation. Precautions against

electrostatic hazards should be in addition to other precautions, such as explosion protection. They should also be consistent with precautions taken to avoid other hazards that may be present, such as ignitions due to other causes, and toxicity. It is important that all sources of risk in a system of work are considered and that a balanced approach to safety covering all risks be considered.

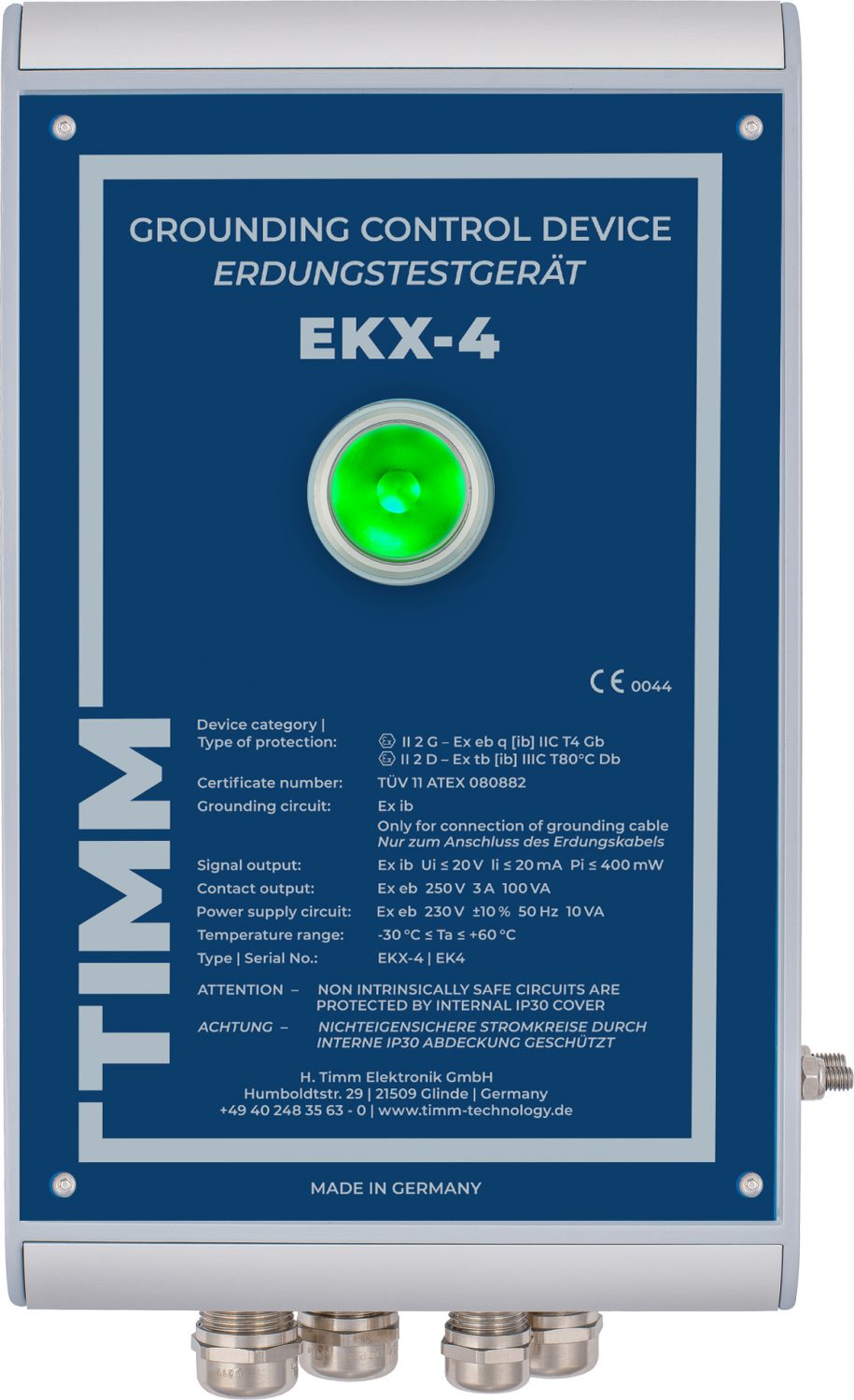

EKX-4 Ground Monitoring Device

The Timm Grounding Control Devices ensure static electricity that could build up on a Road Tanker during filling or unloading is discharged safely to earth, thus avoiding a potential spark risk.

The system will only give the Green Light and release the interlock to pumps etc when the grounding clamp is correctly fitted to the road tanker and will not operate if it is attached to other metal objects such as a tool or the gantry. If the Earth / Ground connection is interrupted, the filling or unloading process will stop immediately.

The Timm device enclosure is purpose-designed for the system and a heavy Exd or Explosionproof box is not required, thus simplifying installation and on-going maintenance.