In Zone 1/21 environments, reliable data capture isn’t just a matter of convenience — it’s essential for safety, compliance, and operational efficiency. Yet, for many technicians and logistics teams, the limitations of conventional barcode scanning equipment present persistent challenges. Access is restricted, line of sight is compromised, and the risks associated with working at height or entering restricted areas are often unavoidable.

The IS-TH2ER.1 from i.safe MOBILE introduces the ideal solution: an intrinsically safe, extended-range barcode scanner built specifically for hazardous areas. With a scanning range of up to 12 metres, integrated IntelliFocus™ technology, and full compatibility with the IS540.1 smartphone via the ISM interface, the IS-TH2ER.1 allows workers to scan from a distance — without compromising safety protocols or operational flow.

Here are three real-world scenarios where that capability makes a tangible difference:

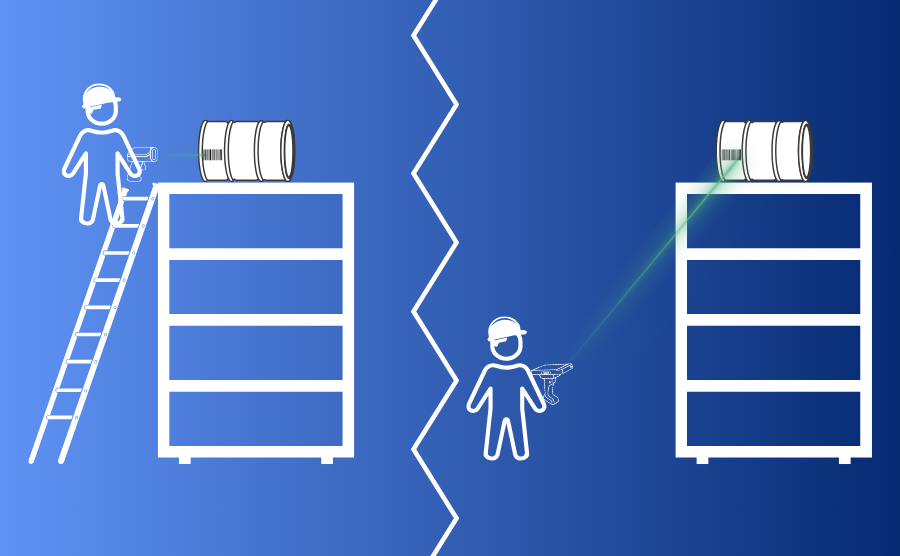

Scanning Asset Tags at Height — From Ground Level

The challenge:

Many sites store process equipment, bulk materials and hazardous materials in high-bay racking or multi-tiered pallet systems. When an engineer needs to verify an asset tag located three, six, or even ten metres above ground, the typical solution involves ladders or mobile access platforms. This not only slows down the task but introduces unnecessary risk.

The solution:

The IS-TH2ER.1’s extended scanning range, supported by the Zebra SE55 scan engine and a precise green laser aim, allows for reliable barcode acquisition from the ground. It can accurately capture 1D or 2D barcodes on elevated assets without manual repositioning or working at height.

Operational benefits:

- Eliminates the need for temporary access equipment or permits

- Speeds up asset identification during inspections or audits

- Reduces safety risk and improves lone worker efficiency

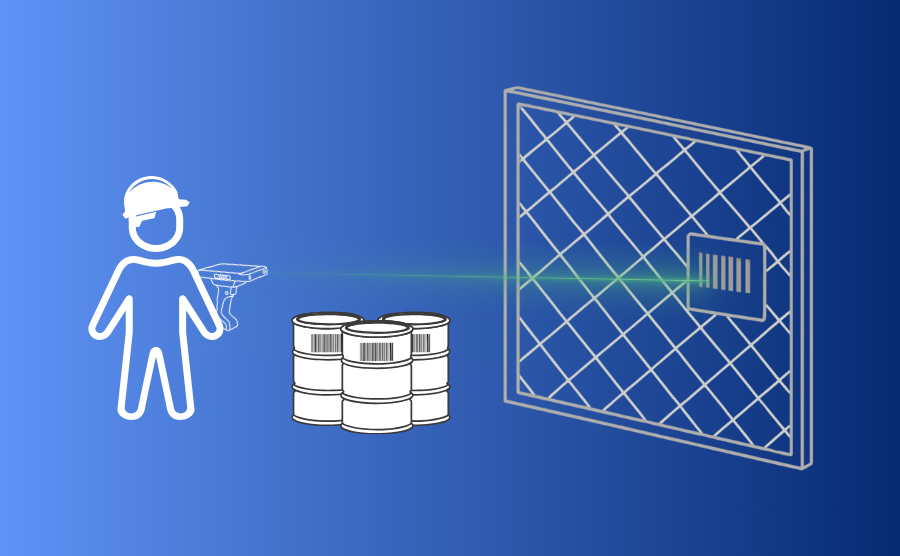

Reading Through Protective Barriers in Hazardous Zones

The challenge:

In many ATEX-rated facilities, sensitive or volatile materials are stored within locked cages, behind mesh enclosures, or behind blast-resistant glass. While these barriers are essential for safety, they create friction during routine verification or inventory tasks, often requiring time-consuming workarounds to physically access the barcode.

The solution:

The IS-TH2ER.1 is engineered to capture barcodes through such barriers, maintaining read accuracy even when scanning through mesh or clear partitions. Its high-resolution sensor (2688 × 1520 pixels) and adaptive IntelliFocus™ optics enable rapid, accurate reads from varied distances and angles — even when the label is partially obscured.

Operational benefits:

- Enables barcode scanning without breaching containment

- Minimises disruption to safety barriers or access controls

- Streamlines workflows involving locked or restricted storage zones

Conducting Stock Audits in ATEX Warehousing and Outdoor Areas

The challenge:

Performing regular stock checks in hazardous-area warehouses or outdoor areas is labour-intensive. In some cases, barcodes are affixed to irregularly shaped or stacked materials, requiring operators to handle or move items manually. Add in PPE requirements, poor lighting, and ATEX restrictions, and the process becomes even more cumbersome.

The solution:

Paired with the IS540.1 smartphone, the IS-TH2ER.1 forms part of a seamless, intrinsically safe scanning system. Dual LED illumination, wide scanning angle, and long-range performance allow users to conduct stocktaking efficiently from a fixed or central position — even when visibility is limited or items are in hard-to-reach locations.

Operational benefits:

- Reduces physical interaction with hazardous or heavy goods

- Increases speed and accuracy of inventory tasks

- Minimises time spent in hazardous environments during audits

Built for the Realities of Hazardous Work

The IS-TH2ER.1 isn’t just about scanning from further away — it’s about transforming the way teams interact with physical assets in the world’s most demanding environments. Its MIL-STD-810H-certified ruggedness, IP68 ingress protection, and seamless power and data integration with the IS540.1 smartphone make it a field-ready tool built for daily use in ATEX Zone 1/21.

For engineers, technicians, and logistics teams working in potentially explosive environments, the benefits of long-range scanning are immediate and measurable: improved safety, reduced downtime, and a leaner, more efficient workflow.

IS-TH2ER.1