R.A Jones & Co (UK) produce a range of equipment for Packaging and filling processes and these include Aerosol filling and pressure testing machinery, both for safe Area and Hazardous Area / Location use.

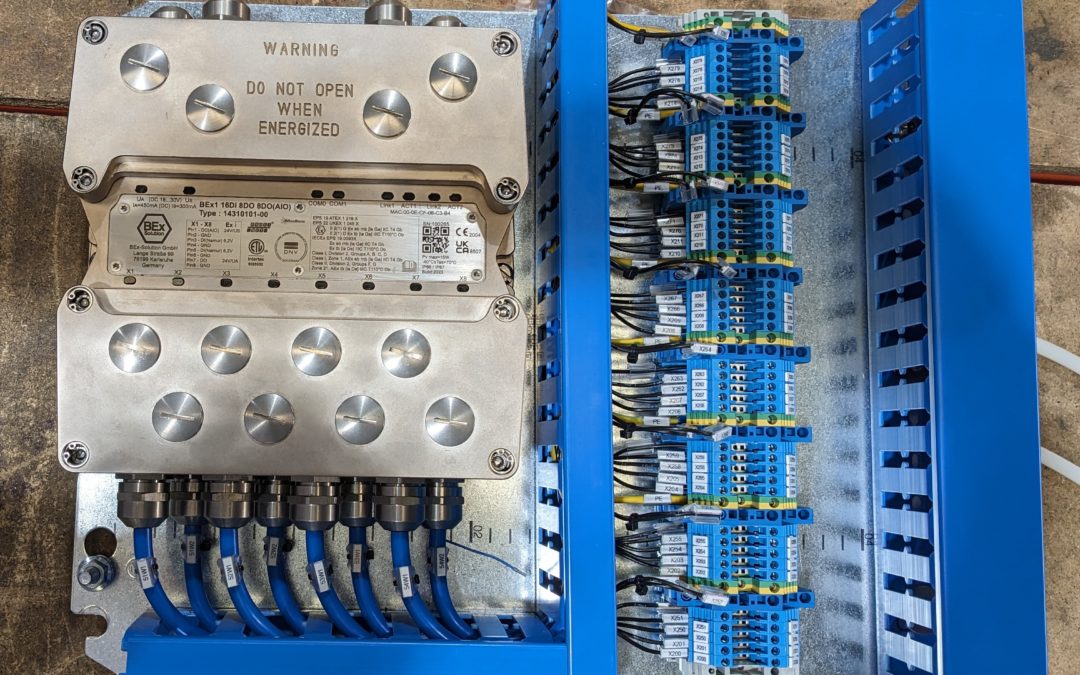

A new High speed 24 head Aerosol filling machine, destined for installation in the USA will be using the latest BEx Solution Remote IO Module, BEx1 approved for use in ATEX Zone 1 and US Class / Division, with Intrinsically Safe outputs.

The machine will be installed in a Class 1 Div 1 Hazardous Location, as it will be filling aerosol cans whose contents include flammable liquid petroleum gas or LPG. Each of three BEx1 units per machine will be linked to eight of the filling heads, providing connection to eight 4-20 mA pressure sensors and 16 digital inputs, two per head.

The BEx1 units were considered to provide a clean, self-contained, compact and affordable solution, that would otherwise have involved Bus-based I-O utilising multiple individual slots per channel leading to increased component count and a larger install space.

The RA Jones equipment viewed, also included a line for creating an overpressure of several times the normal expected pressure in each individual can, to ensure that no can could accidentally explode in normal usage. This was achieved by holding each can in a bath of water at 50°C, to cause extra liquid LPG to become gaseous.

Our thanks to Leon Finn, Aerosol Technical Specialist R.A Jones for giving us access to and discussing their equipment with us.