In hazardous environments where explosive atmospheres may be present, safety and compliance are non-negotiable. Fire suppression systems are critical assets in these zones — but the routine maintenance and inspection of their pressurised cylinders has traditionally posed challenges. Manual handling risks, hot work permits, and costly downtime are often unavoidable when using conventional methods such as weighing.

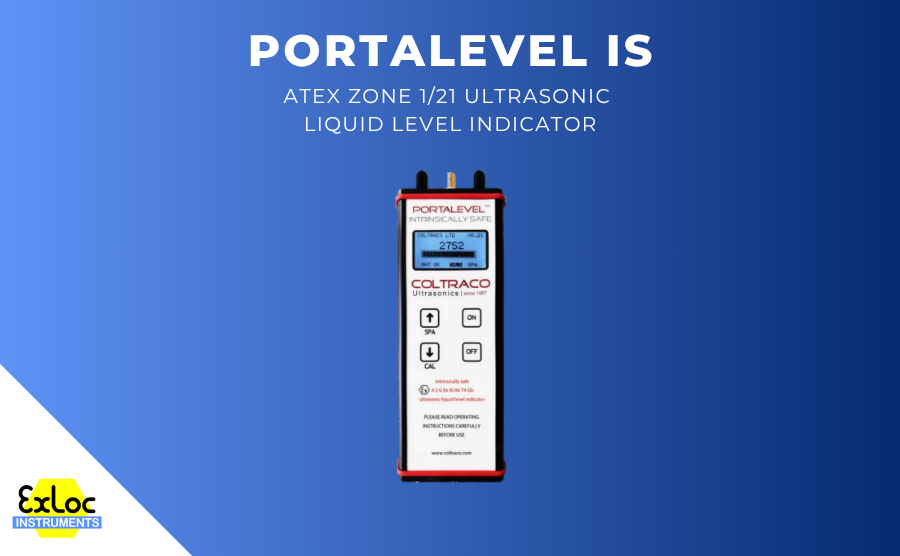

Now, there’s a smarter way. The Portalevel® IS from Coltraco Ultrasonics is an intrinsically safe liquid level indicator specifically engineered for ATEX Zone 1 / 21 areas – delivering speed, accuracy, and safety in a compact, certified solution.

Intrinsically Safe by Design: Certified for ATEX Zone 1 / 21

The Portalevel® IS is both ATEX and IECEx certification (II 2 G Ex ib IIA T4 Gb), meaning it can be safely operated in Zone 1 / 21 and Zone 2 / 22 hazardous areas — even during live fire suppression system checks.

The unit’s design prioritises safety from the inside out. Powered by a single AA battery, with no hot surfaces or sparking risk, removing the need for hot work permits and simplifying on-site compliance.

For sites governed by DSEAR or operating under COMAH regulations, this level of certification is vital. It provides peace of mind for operators and makes scheduled maintenance more manageable — especially in large-scale, multicylinder installations across oil & gas, chemicals, power generation, and aviation infrastructure.

Non-Invasive Accuracy That Saves Time and Reduces Risk

Where weighing requires shutting down systems and often removing heavy cylinders, the Portalevel® IS uses ultrasonic liquid level detection to carry out checks in situ — in less than 30 seconds per cylinder. It’s a one-person operation with no manual handling risks, no lifting equipment, and no interruption to business operations.

The device offers an accuracy of ±1.5 mm, with a simple digital display and intuitive bar-graph echo indicator that makes identifying the liquid level straightforward — even in high-vibration or low-access areas.

For assets with varied surface materials or particularly narrow cylinders, the Portalevel® IS includes four power settings, including a Special Power Application (SPA) mode that enhances signal clarity in more difficult measurement conditions. Combined with three calibration modes, it can be easily tuned to specific suppression agents such as CO₂, FM-200®, Novec™ 1230, and others.

A Case Scenario: Efficiency and Safety in an LNG Terminal

Imagine a typical LNG terminal in the UK, a facility with extensive fire suppression coverage across process areas, storage zones, and control buildings. Fire safety teams are required to carry out biannual cylinder checks to maintain compliance with ISO 14520 and site-specific HSE protocols.

Traditionally, this would mean arranging system shutdowns, mobilising lifting equipment, and coordinating multi-person teams, a process that might stretch over several days. The knock-on effects? Increased labour hours, production disruption, and elevated risk from manual handling in confined zones.

By contrast, with the Portalevel® IS, a single trained technician can move from zone to zone, performing live level checks without system isolation. With each reading completed in under a minute, full-system inspections can be achieved in hours rather than days — delivering significant cost savings while maintaining the highest safety standards.

Designed for the Field: Built to Last, Backed for Life

Weighing just 480 g and supplied with a durable ultrasonic sensor and BNC cable, the Portalevel® IS is compact enough to be carried comfortably around large installations. It operates effectively in temperatures from –20°C to +40°C, with a straightforward interface that requires minimal training.

Each unit is built in the UK and comes with a three-year warranty as standard, supported by Coltraco’s long-standing calibration services and a full accessory kit including sensor, gel, and protective carry case.

When paired with the Portasteele® Calculator (a separate software-based tool), the Portalevel® IS can also be used to convert liquid level readings into weight, offering a full audit trail for regulatory records.

Supporting Compliance and Long-Term Safety

The Portalevel® IS supports compliance with key international standards, including NFPA 2001, ISO 14520, and SOLAS FSS Code, making it suitable for both land-based and marine applications.

Because the device allows live checks without interfering with system integrity, site managers can meet their obligations without introducing additional hazards — and without pushing inspection routines into periods of planned shutdown.

The Right Tool for High-Risk Environments

Routine cylinder monitoring is critical, but in hazardous zones, it’s often avoided, delayed, or compromised due to the complexity and cost of traditional approaches. The Portalevel® IS removes those barriers, giving safety teams a practical, compliant, and intrinsically safe solution that saves time and money while significantly reducing risk.

To find out more about how the Portalevel® IS can transform your approach to fire suppression system maintenance in hazardous areas, contact Exloc today!