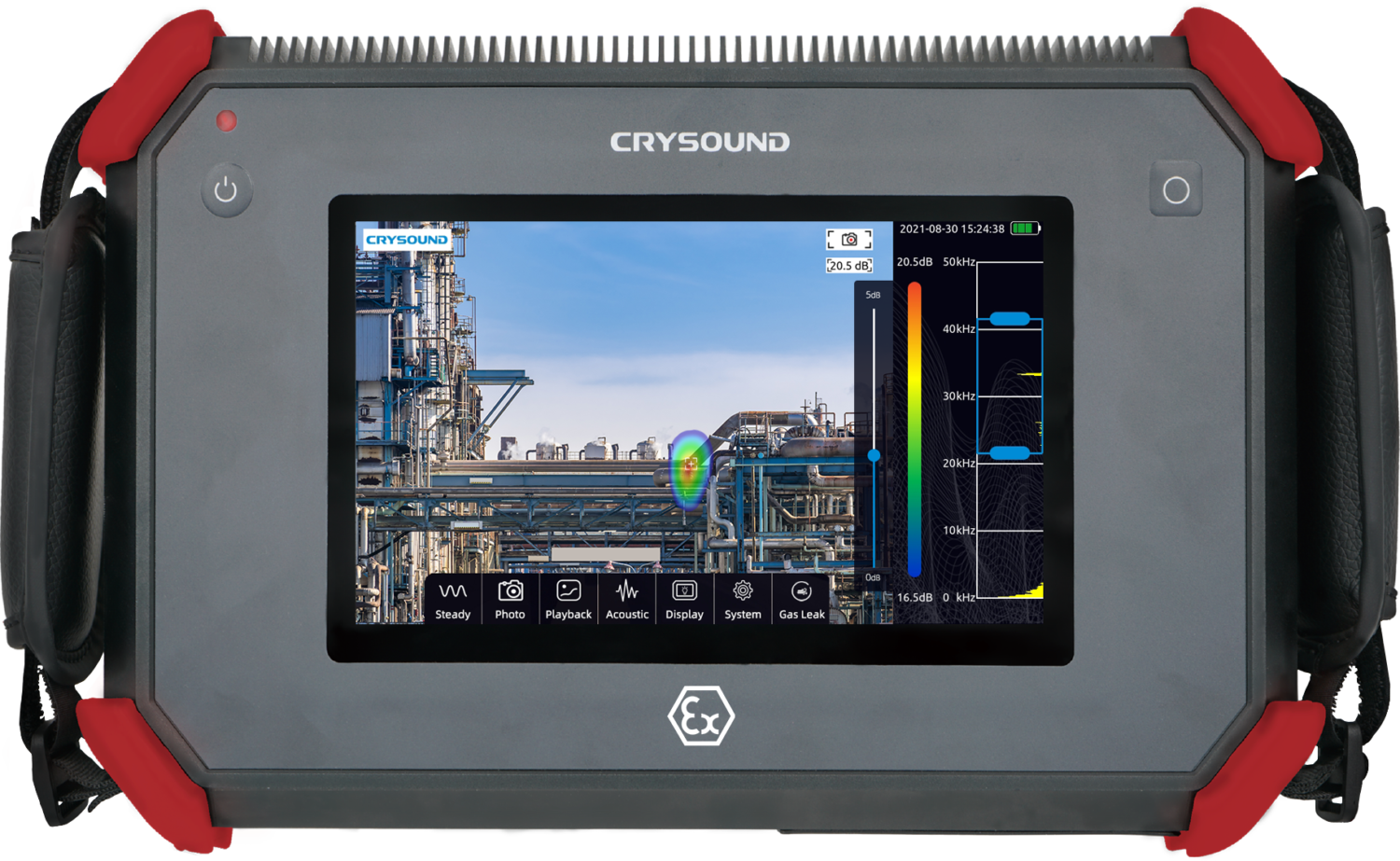

CRY2624

ATEX Industrial Acoustic Imager

CRY2624 ATEX Zone 2

The CRY2624 Industrial Acoustic Imager is a state-of-the-art device designed for the precise detection of gas leaks in hazardous environments, particularly within the chemical and energy industries. Constructed with a robust aluminium alloy shell, it is engineered to withstand complex and challenging working conditions, ensuring reliable performance and durability.

The imager operates by converting sound waves into visual images, allowing for the swift and accurate identification of leaks from pressurised or vacuum systems. This real-time sound imaging capability is crucial for maintaining safety and efficiency in industrial settings, where undetected leaks can lead to significant safety hazards and economic losses.

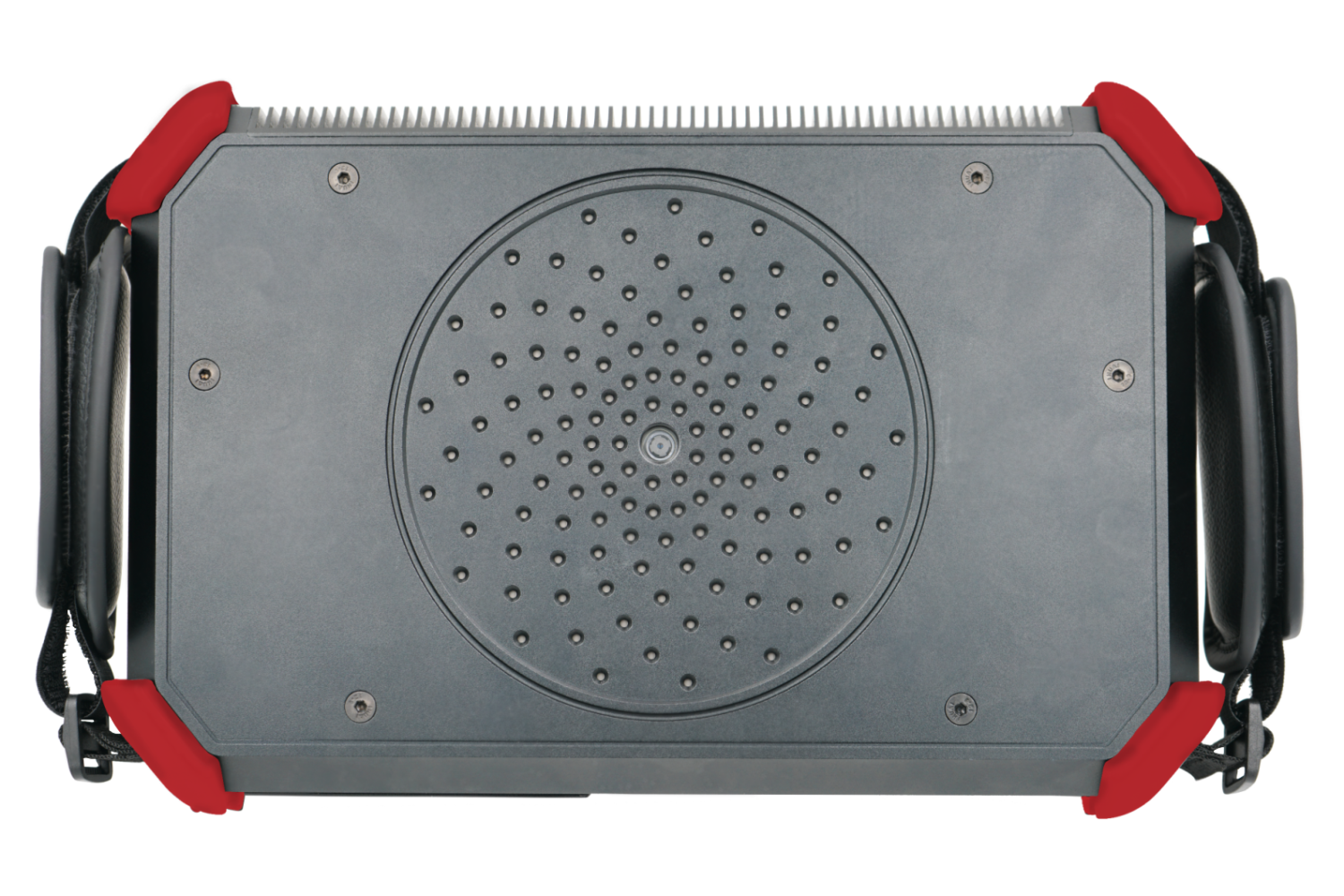

Key to its functionality is the use of 128 digital MEMS microphones, which provide high sensitivity and resolution. This array of microphones enables the device to capture minute acoustic signals, translating them into clear visual data that can be easily interpreted by operators.

Additionally, the CRY2624 is equipped with advanced features for the continuous display and assessment of leak severity. This allows for the prioritisation of maintenance efforts and helps in preventing minor leaks from developing into major issues. The device also has capabilities for detecting partial discharges, which are early indicators of potential electrical faults, thereby contributing to overall system reliability and safety.

For compliance and reporting, the CRY2624 generates detailed analytic reports that adhere to ISO 50001 standards. These reports are invaluable for energy management and regulatory compliance, providing clear documentation of leak detection activities and findings.

Overall, the CRY2624 Industrial Acoustic Imager represents a critical tool for modern industrial maintenance, combining advanced acoustic technology with user-friendly operation to enhance safety and efficiency in hazardous environments.

Key Features

- High-Sensitivity Detection: Utilises 128 digital MEMS microphones for high sensitivity, sound resolution, and accuracy.

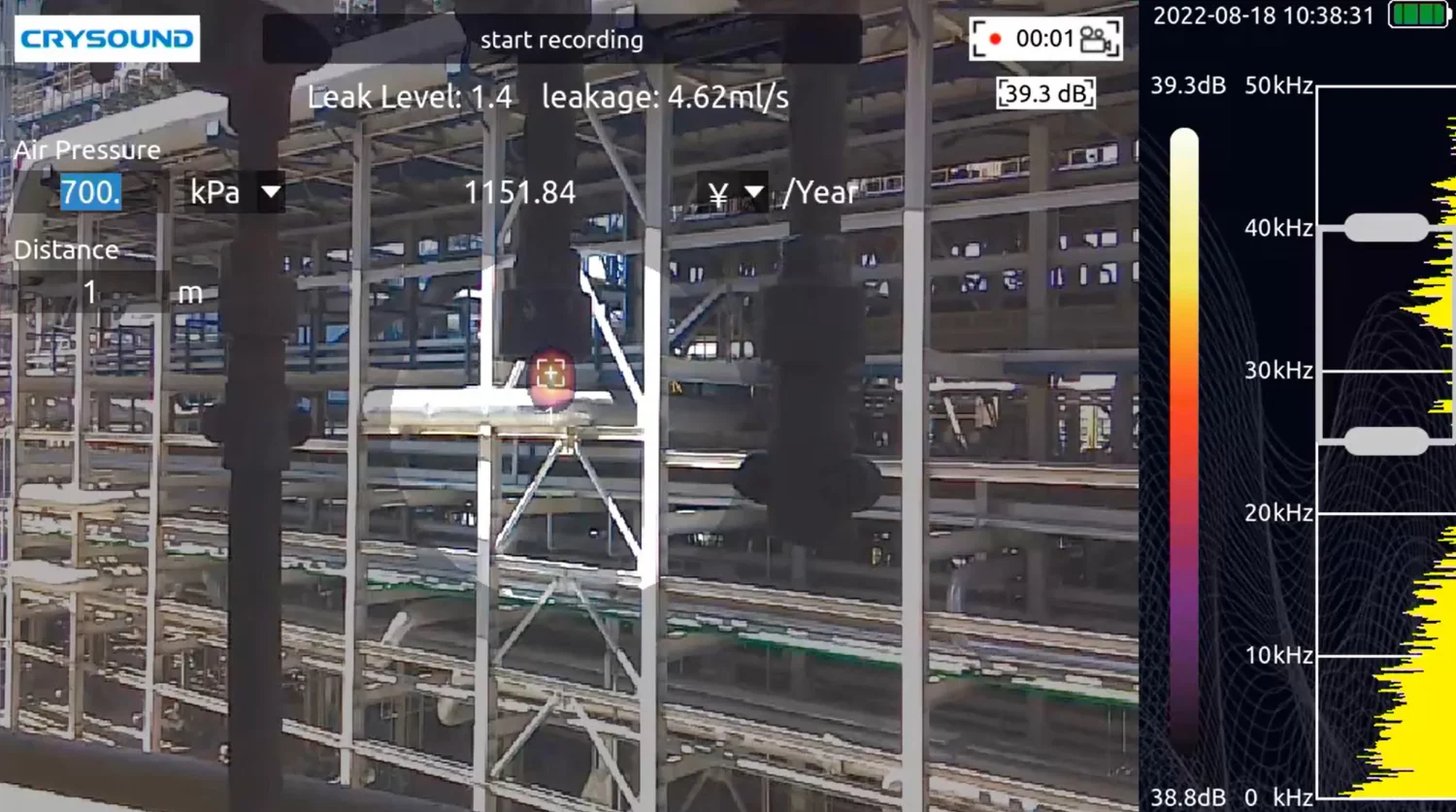

- Leakage Assessment: Continuously displays the amount and severity of leaks.

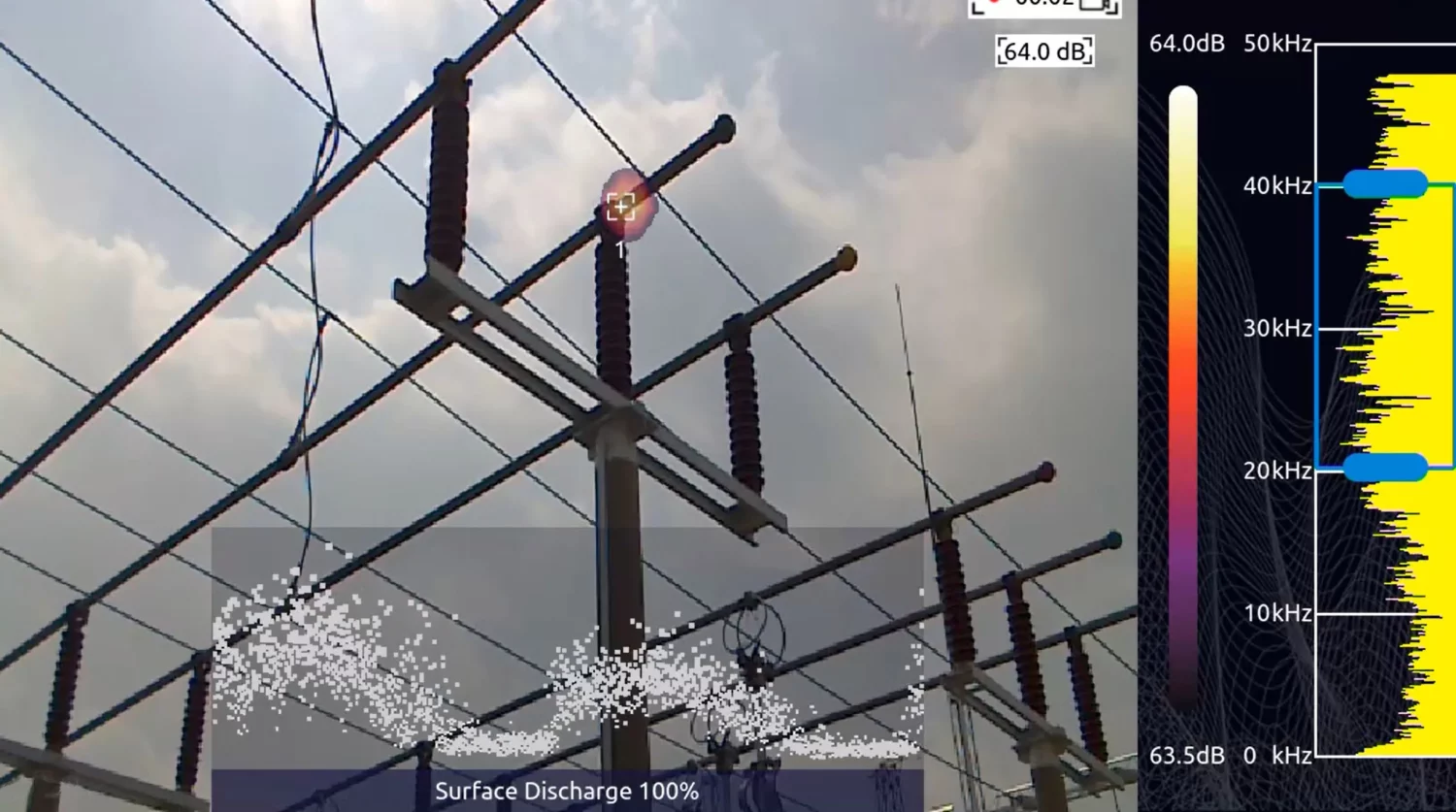

- Partial Discharge Detection: Identifies partial discharges before they escalate into serious faults.

- Analytics and Reporting: Generates ISO 50001 compliant reports with data visualisation tools.

Features

High-Performance Microphones for Efficient Detection With ATEX Certification

128 digital MEMS microphones can provide exceptionally high sensitivity, sound resolution and detection accuracy, real-time audio-visual display, anti-jamming, help detection.

Leakage Assessment

By activating the leak measurement function, the camera continuously displays the amount of leaks and losses as well as the level of loss.

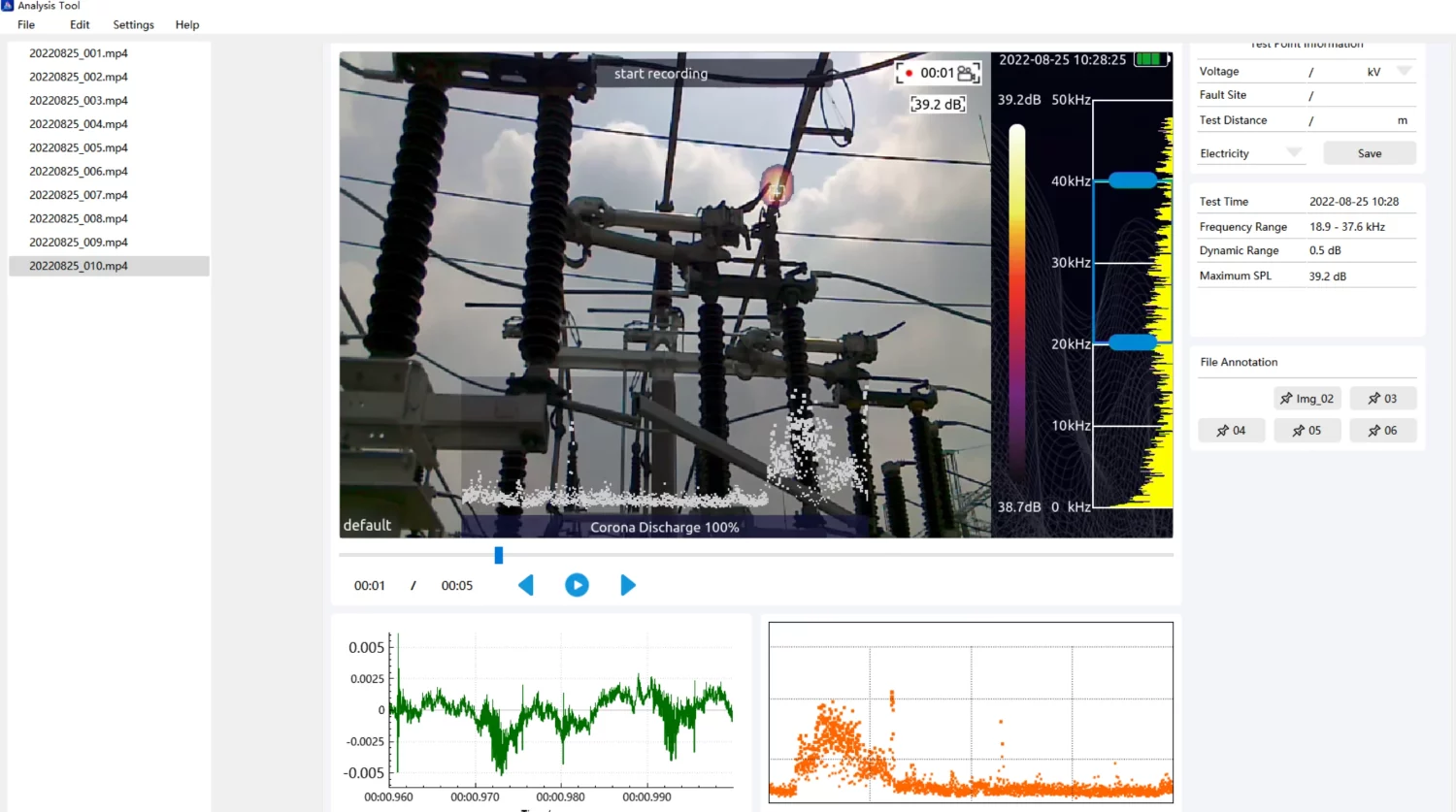

PD Detection & PD Type Identification

Partial discharges can be detected before more serious faults would occur, even before a thermal camera would detect them.

Analytics and Reports

Template-based processing and recording of data, waveforms,spectra,spectrograms is supported by CRYSOUND report analysis tool software, generating ISO 50001 compliant, editable protocols in Excel format.

| Acoustic Specification |

|---|

| Microphone array | 128 channels MEMS microphone |

| Effective test bandwidth | 2kHz-48kHz |

| Dynamic range | 0.5dB-12dB user adjustable |

|

Test sound pressure level range |

25.7-132.5dBA |

| Auto max/min dB gain |

User-settable, minimum test bandwidth 1kHz |

| Number of digits | 24bit |

| Sound image FOV | 62° |

| Sound image frame rate | At least 25 FPS |

| Leak detection rate |

10m 5bar 0.92ml/s 0.5m 5bar 0.55ml/s |

| Detect distances | 0.3m-120m |

| Camera |

|---|

| Camera FOV | 62° |

| Camera focal length | 3.04mm fixed focal length |

| Camera pixel | 8 million pixel |

| Display |

|---|

| Resolution | 1024*600 (614,400 pixels) |

| Size | 7 inch |

| Touch screen | Capacitive touch screen |

| Brightness | Adjustable |

| Photo notes | Up to 5 photos notes for reference |

| Source | Show single or multiple sources |

| Standard palettes | 3: Grayscale, Ironbow, Blue-Red |

| Playback function |

View photos, videos anytime, and add notes or tags |

| Storage |

|---|

| Internal storage | About 8G |

| External storage |

TF memory card, at least 64G, expandable to 256G |

| Data storage format |

jpg(Picture), mp4(Video)wav (Audio) |

| Video length | 5 minutes |

| Digital export | TF Card |

| Power |

|---|

| Battery capacity |

1×6600mAH@7.2V Rechargeable battery and 1×external battery package, continuous |

| Battery life | 4+6 hours operation time |

| Charger |

USB Type-C port, USB PD protocol supported, 15W |

| Power consumption |

15W for battery charge; 29W for maximum power consumption |

| Energy management | Sleep/Auto power off modes |

| Interface |

|---|

| USB 3.0 Type-C USB host port |

| 3.5mm headphone socket |

| Operating Environment |

|---|

| Operating environment |

-20℃ – +50℃, 10%-95% no condensation |

| Storage temperature | -20℃ – +60℃ |

| Charging temperature | 10℃ – +45℃ |

| General Specification |

|---|

| Ingress Protection (IP) | IP54 |

| Size | 272mm×174mm×42mm |

| Weight | 1.7kg |

| Warranty | 2 years |

|

Self-diagnostic notification |

Array-health test function to identify when microphone array needs attention |

| System | Linux system |

| Certification |

|---|

| ATEX (II 3G Ex ic IIC T5 Gc), CE, FCC, RoHS-compliant, MSDS, CNEX |

| Supported Language |

|---|

| English, French, Chinese, German, Italian, Japanese, Korean, Norwegian, Polish, Portuguese, Russian, Spanish, Swedish |

| Software |

|---|

| Report types |

Gas/Electricity, ISO 50001-compliant |

| Analysis |

Waveform, Spectrum, Spectrogram, leakage assessment, discharge type discrimination |